Complexities abound in the manufacturing of many components, but the precision and expertise required for manufacturing aerospace parts surpasses any other industry.

Aerospace components can require tolerances of two microns or less – for comparison, hair is about 50 microns – and marginally imprecise components can dramatically impact performance and safety during flight.

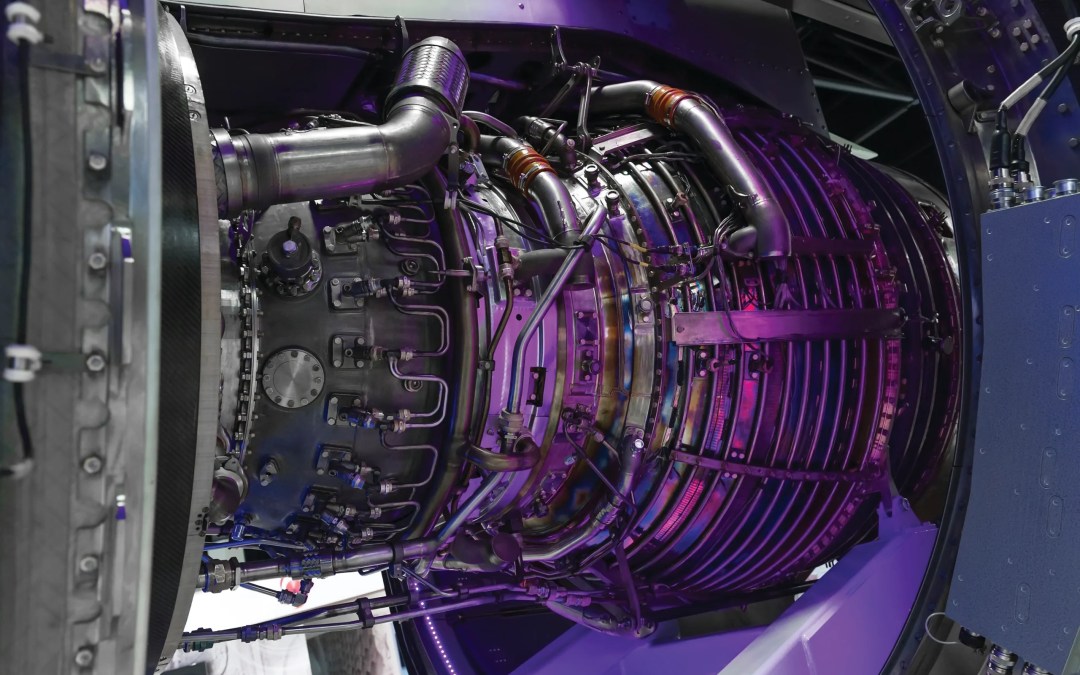

Complex geometries, component composition and strict quality control and compliance add to the pressure that manufacturers face on a daily basis. Escalating demand has intensified the pace at which manufacturers must produce parts for commercial and military aircraft with no margin for error.

All those factors contribute to the difficulty of manufacturing components for the aerospace industry. The most significant hurdle, however, is meeting the extreme demands for precision. Few manufacturers have processes, such as electroforming, deep drawing, and spinning to manufacture components that meet the exacting demands of the aerospace industry.

Alpha Metalcraft Group uses its deep drawing and spinning capabilities to produce an array of components for aerospace manufacturers. Piccolo duct components, tank liners, heat shields and fuel system housings and enclosures are all essential components with unique shapes and are manufactured with different materials.

Piccolo ducts, for instance, are used in anti-ice systems and are circular assemblies made with titanium, stainless steel and/or nickel. The tubes are manufactured to a tolerance of 50 thousandths of an inch over their diameter. Heat shields, which are used in brake systems, are made with aluminum or stainless steel for aircraft. Aluminum is lightweight and a good conductor of heat, while stainless steel offers strength and durability and stands up in high stress environments.

Deep drawing and spinning produce complex geometric and highly precise shapes quickly and efficiently and offer the ability to produce components in large quantities. Deep drawing and spinning allow AMG to manufacture large and heavy components with exotic metals. In most instances, no additional processing is required. Deep drawing and spinning also limit material waste, another critical benefit.

Electroforming is a much different manufacturing process, but it offers similar advantages to deep drawing and spinning.

Some components made via electroforming/electroplating include rocket thrust chamber fuel passage encapsulating jackets, composite blades leading edge guards, micro turbine products such as outer cases, exhaust nozzles, and combustor liners as well as missile components.

Leading edge guards are made with nickel-cobalt alloys. They are selected for their durability, resistance to corrosion and ability to withstand harsh conditions. Copper and nickel alloys are commonly used in rocket thrust chambers and are used due to their ability to withstand high temperatures and pressure while maintaining structural integrity.

The process allows for reproduction of the external shape of a mandrel within one micrometer – about 0.000039 inches. With electroforming, AMG can manufacture large, heavy and oversized components. AMG manufactures a rotor blade leading edge guard that is 17 feet long within a few days and can make parts up to 3,000 pounds. Electroforming can also produce components in large production runs.

The ability of deep drawing, spinning and electroforming to meet exacting tolerances enabled AMG to acquire a critical certification. All AMG manufacturing sites are AS9100D certified, which is an international standard for Quality Management System requirements for aviation, space and defense organizations. It is prepared by the International Aerospace Quality group and is a common requirement for manufacturers who provide parts for the aerospace industry.